Interior walls bowing outward are never normal and should always be taken seriously. If you notice a wall bulging or curving, it often points to foundation issues or significant structural problems. Ignoring it can lead to more severe damage over time.

Many homeowners assume a bulging wall is just cosmetic and think a quick patch or paint job will fix it. In reality, this is a structural concern. Foundation failure can result in wall collapse, basement leaks, and unsafe conditions in your home.

This guide will walk you through why walls bow out, the warning signs to watch for, and the repair options that actually work. Acting early is crucial, as catching these issues promptly can save you from costly damage. You’ll also learn when to call a professional and how to prevent problems in the future.

What Is an Interior Wall Bowing Out?

Let me explain what you’re actually looking at when your wall bows. It’s not complicated, but understanding it helps you take the right action.

Wall bowing means the center bulges out while the top and bottom stay mostly fixed. Think of it like pushing the middle of a ruler – the ends stay put, but the center curves. This happens gradually over time, not overnight.

This is different from a leaning wall, where the entire wall slants forward or backward. Bowing is always structural, never cosmetic. It means your foundation is under serious pressure and starting to fail. Don’t let anyone tell you this is just cracking plaster you can patch.

Primary Causes of Interior Walls Bowing Out

Several forces can push your walls out of alignment. Understanding the cause helps you fix it permanently instead of just patching symptoms.

Hydrostatic Pressure (The Most Common Cause)

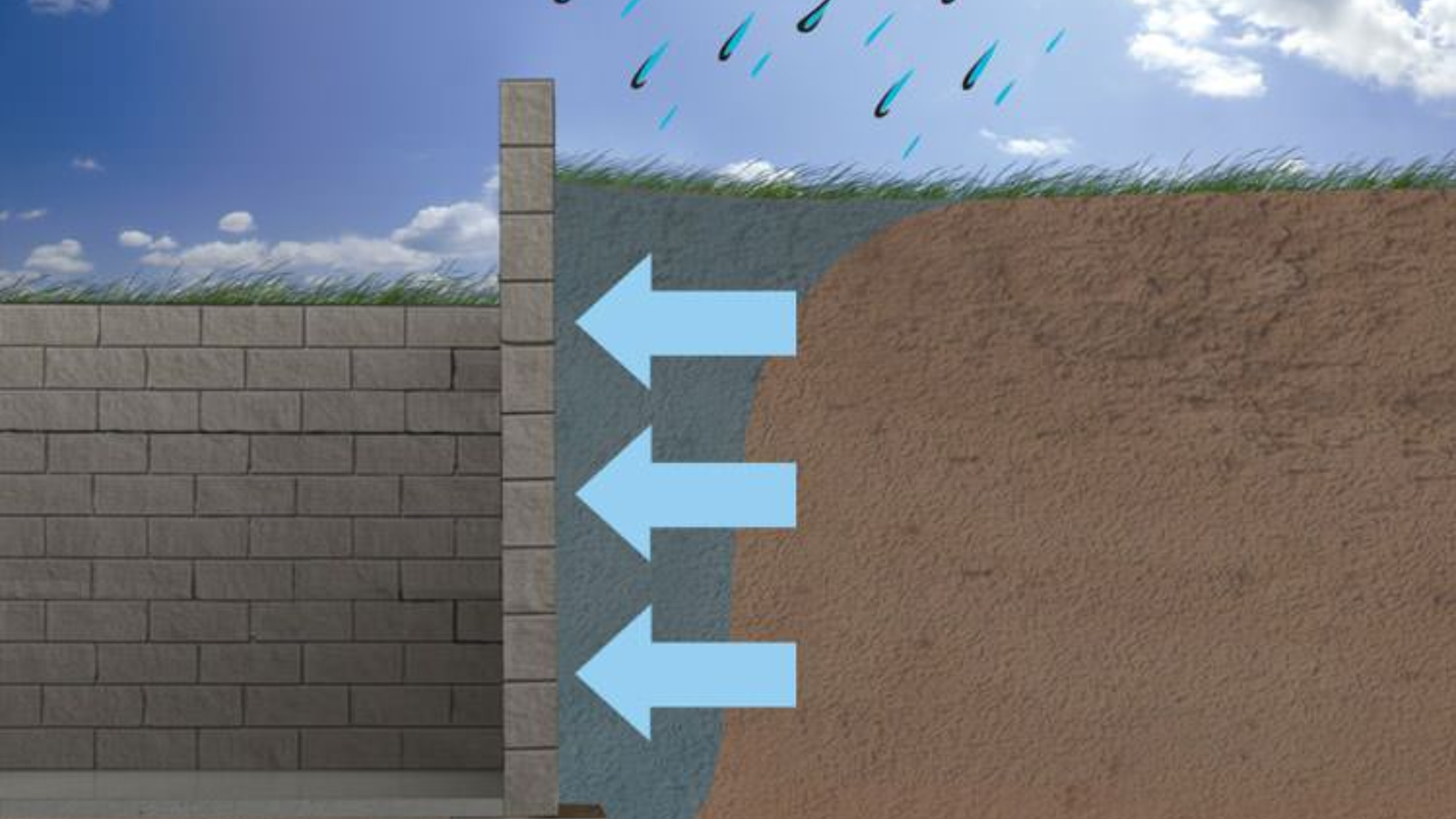

Water-saturated soil is often the main cause of bowing walls. When clay soil beneath your foundation becomes soaked, it expands and pushes outward with significant force.

Standing water under your home adds even more pressure, especially during wet seasons from rain, poor drainage, or high water tables. Regions with heavy precipitation, lakes, or wetlands are particularly prone to hydrostatic pressure on basement walls.

Expansive Soil Movement

Clay soil expands when wet and shrinks when dry. This constant expansion and contraction puts uneven pressure on your foundation walls. California and Arizona deal with this a lot because of their clay-heavy soils.

In cold climates, freeze-thaw cycles cause soil to expand and contract, pushing against walls repeatedly. Over time, this constant shifting weakens the wall structure, even though it happens unseen underground.

Poor Drainage and Water Management

Pooling water around your foundation is a serious concern. Rainwater or sprinkler runoff that doesn’t drain properly soaks into the soil, adding weight and pressure against your walls.

Poor drainage, like negative grading, clogged gutters, or standing water, adds pressure to walls. Fixing these issues helps prevent wall movement.

Structural and Load-Related Issues

Sometimes bowed walls result from construction issues. If studs were undersized, spaced incorrectly, or poorly placed, walls may lack the strength to handle normal pressures.

Removing load-bearing walls, large additions, or heavy objects nearby can put pressure on your foundation. Vehicles and equipment may also compress soil, adding pressure to walls.

Age and Deterioration Factors

Older homes bow more due to decades of wear, moisture, and pests weakening studs, joists, and masonry, increasing wall pressure.

Older homes can develop bowing walls due to poor drainage, settling, and soil movement gradually weaken their structure over time.

Critical Warning Signs to Watch For

You need to know what to look for before the problem becomes critical. Some signs are obvious, others are subtle.

Visual Indicators on the Wall Itself

Horizontal cracks across the middle of a wall are often the first warning sign of structural issues. Homeowners usually notice these cracks before anything else, and they should never be ignored.

Other warning signs include bulging or curving walls, stair-step cracks in masonry, and tilting that makes walls appear to slide inward at the top or bottom. Expanding cracks over time indicate worsening conditions and a potentially serious problem.

Gaps and Separation Issues

Gaps forming between your wall and floor mean the wall is moving. The separation between the wall and the ceiling shows the same thing. These aren’t normal settling cracks – they’re structural movement.

Doors or windows that suddenly stick or won’t close properly signal wall movement. Frames that are no longer square or aligned indicate shifting. You’ll see visible space where the wall meets other surfaces. This is your home telling you something is seriously wrong.

Water-Related Warning Signs

Water leaking through wall cracks is a serious warning sign, indicating both wall bowing and water intrusion issues. Standing water around your home or in the crawlspace creates pressure that pushes against the walls, causing them to bow.

Watch for signs like musty odors from excessive moisture, mold growth on lower walls or in the crawlspace, and mold appearing under flooring. Efflorescence, the white chalky deposits on masonry, shows that water is passing through your foundation regularly.

External Factors Contributing to the Problem

Recent floods or heavy rain affecting your property often trigger bowing. The soil gets saturated, expands, and pushes. Trees and shrubs planted too close to your home create problems, too. Their root systems press against your foundation as they grow.

Negative grading that slopes toward your foundation instead of away from it directs all water to the worst possible place. If you don’t have a proper drainage system, water has nowhere to go but into your soil. Visibly saturated soil near your foundation means trouble is already brewing.

How Does Interior Wall Bowing Develop Over Time?

Wall bowing doesn’t happen suddenly. Understanding how it progresses helps you catch it early.

The Progressive Nature of Bowing

Walls don’t bow overnight – it’s a slow, gradual process. You might not notice anything in the early stages. A small crack here, a tiny bulge there. Easy to overlook.

If left untreated, the problem worsens over time. Expansion and contraction cycles make small cracks grow and slight bulges more pronounced, turning minor issues into serious structural concerns.

When External Pressure Exceeds Wall Capacity

Bowing happens when external forces exceed your wall’s load-bearing capacity. Your wall faces two problems at once. It’s losing compressive strength over time, AND external pressure is pushing against it. When those two factors combine, the wall starts to bend.

Once the pressure threshold is exceeded, your wall begins its slow bend. Movement increases as pressure continues or gets worse. Each wet season adds more pressure. Every freeze-thaw cycle compounds the damage. The problem feeds on itself.

Permanent Repair Solutions for Bowing Walls

Three main methods fix bowing walls permanently. Each one works for specific situations.

Wall Anchors (For Significant Movement Over 2 Inches)

Wall anchors use a steel plate inside your basement connected to another plate buried outside. A steel rod links the two plates, and tightening it pulls the wall back into position for a permanent fix.

This method works best for walls with several inches of bowing. Installation requires yard space for the external plate, but it provides a strong, long-term solution that other methods can’t match.

Carbon Fiber Straps (For Slight to Moderate Bowing Under 2 Inches)

Thin carbon fiber straps are bonded directly to your wall with epoxy and installed vertically. Once in place, they are nearly invisible and allow you to finish your basement without interference.

These straps work best for early-stage bowing, stabilizing the wall to prevent further movement. They don’t straighten the wall but act like brakes, stopping the problem before it worsens.

Steel I-Beams/Wall Bracing (For Limited Outdoor Access)

Steel I-beams are installed vertically, anchored to the basement floor and ceiling joists, providing strong support against inward wall movement. They act like braces, holding up leaning walls effectively.

This method is ideal when outdoor access is limited, such as with decks, patios, or landscaping in the way. The beams remain visible inside but add serious structural strength without disturbing your yard.

Why DIY Fixes Don’t Work

Patching cracks or applying waterproof paint only masks the problem. These cosmetic fixes don’t stop the pressure pushing against your wall, so the bowing continues over time.

Permanent solutions like wall anchors, braces, or carbon fiber are necessary. DIY attempts may save money briefly, but ignoring the underlying issue can lead to far more expensive repairs later.

Prevention and Long-Term Protection

Fixing bowing walls is expensive. Preventing them is much cheaper.

- Address Water and Drainage: Regrade your yard to direct water away and maintain gutters and downspouts. Use drains or sump pumps in high water table areas.

- Regular Foundation Inspections: Have a professional check your foundation yearly and monitor cracks with photos to catch early issues.

- Manage Landscaping and Soil Moisture: Fix drainage problems promptly and plant trees at least 20 feet from the foundation.

- Proper Stud Support: Ensure studs are correctly sized and supported. Never remove load-bearing walls without an engineer.

- Avoid Excessive Loads: Maintain proper wall placement and keep heavy vehicles or equipment away from the foundation.

When to Call a Professional?

Some warning signs demand immediate professional attention. Don’t wait on these.

- Immediate Warning Signs: Horizontal cracks, bulging walls, water leaks, sticking doors, or new gaps indicate serious foundation issues requiring prompt professional attention.

- Comprehensive Evaluation: Professionals inspect your entire foundation, assess bowing severity, and identify underlying causes.

- Structural Integrity Testing: Experts determine how much strength your walls have lost and provide a customized repair plan.

- Expert Tools and Knowledge: Proper diagnosis ensures repairs target the real problem and prevent future issues.

- Avoid DIY Risks: Attempting repairs yourself can worsen structural damage, while professional work ensures safe, lasting results with warranties.

Conclusion

Interior walls bowing outward signal serious foundation problems that need prompt attention. Common causes include water pressure from saturated soil, poor drainage, expansive clay soil, and structural weaknesses. Watch for horizontal cracks, bulging walls, water seeping through, or gaps between walls and floors, as these indicate your foundation is under stress.

DIY fixes might seem easy, but they cannot solve the underlying issues. Permanent repair requires professional solutions like wall anchors, carbon fiber straps, or steel beams to stabilize walls and prevent further movement. Early intervention saves thousands compared to waiting for severe damage.

Many foundation companies offer free inspections and financing options, making professional help more accessible. Protecting your home and family should always be the top priority, so don’t delay in addressing any warning signs.

Frequently Asked Questions

Is an interior wall bowing out dangerous?

Yes, it indicates serious foundation or structural problems that can lead to wall collapse, flooding, and unsafe living conditions if ignored. The problem worsens progressively over time.

What is the most common cause of interior walls bowing out?

Hydrostatic pressure from water-saturated soil pushing against foundation walls is the most common cause. Poor drainage, expansive clay soil, and standing water around the home contribute to this pressure.

Can I fix a bowing wall myself?

No, not permanently. Patching cracks or applying waterproof paint doesn’t fix the actual pressure causing the bowing. You need professional structural solutions like wall anchors, carbon fiber straps, or steel I-beams.

How much does it cost to fix an interior wall bowing out?

Costs vary based on severity, repair method, and number of walls affected. Minor repairs with carbon fiber may cost less than severe bowing requiring wall anchors. Get free professional inspections for accurate estimates.

How quickly does wall bowing progress?

Wall bowing is a slow, gradual process that develops over months or years. However, once it starts, it progressively worsens, especially during wet seasons or freeze-thaw cycles. Early intervention prevents severe damage.