You may hear contractors talk about CMU walls and feel unsure what they mean. The term sounds technical, but the idea is simple. CMU stands for Concrete Masonry Unit, which is the concrete block used in many types of construction.

These blocks are common in schools, warehouses, and home foundations. Knowing what CMU walls are helps you understand cost, build time, and long-term performance. Builders rely on them because they solve many practical needs on a job site.

CMU walls have been used for decades because they are strong, fire-resistant, and often more affordable than other materials. They work for small residential projects and large commercial buildings.

This guide explains what CMU walls are, their strengths and limits, and how they compare to other building options, based on real experience.

CMU Wall Meaning: Breaking Down the Definition

CMU is construction shorthand that often confuses. It stands for Concrete Masonry Unit, which is simply the official name for standard concrete blocks used on job sites.

These blocks are precast and manufactured to strict size and strength standards.

CMU blocks are made from basic materials mixed in exact ratios. Portland cement binds the aggregates, water activates the mix, and mortar holds the blocks together in a wall. Some blocks also include pigments for added color.

CMU has been used since the early 20th century as builders looked for stronger, more reliable materials.

Over time, block designs evolved to meet different needs. Their durability, versatility, and lower cost made CMU a construction staple.

How CMU Blocks Are Made?

Understanding how CMU blocks are made helps explain their strength and reliability. The process begins by mixing raw materials in precise ratios, since incorrect proportions weaken the block. The mix is poured into molds and compacted to remove air pockets.

Quality control is built into every production stage. Manufacturers test each batch for strength and density to meet construction standards. Blocks that fail these tests are rejected before leaving the factory.

After molding, blocks cure in steam kilns for 12–18 hours to gain strength without cracking. They are then dried, stacked on pallets, and wrapped for protection. From mixing to shipping, the full process takes several days.

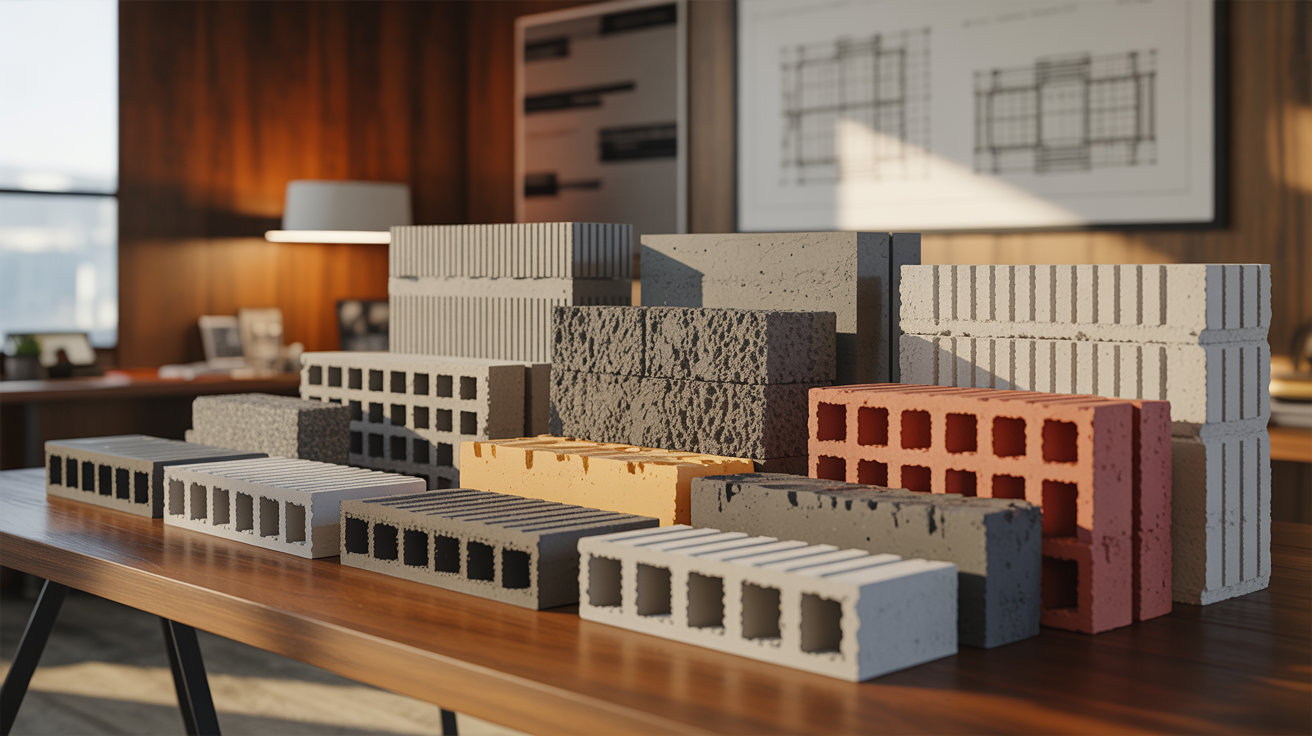

Types of CMU Blocks Available

CMU comes in way more varieties than most people realize. Different projects need different block types.

Standard CMU Blocks

The most common type measures 8x8x16 inches. This size became standard because it works for most applications and is easy to handle.

Various sizes and shapes exist for different construction needs. Standard CMU gets used in foundations, walls, and partitions everywhere. It’s cost-effective and readily available at any building supply store.

Structural Design CMU Blocks

These blocks are designed with looks in mind. Structural design CMU comes in various textures, colors, and finishes that regular blocks don’t offer.

You’ll see these in decorative facades and feature walls where appearance matters. They balance visual appeal with structural functionality. They cost more than standard blocks but look way better.

Specialty CMU Blocks

Specialty CMU blocks are designed to handle specific building challenges. Options include insulated CMU for energy efficiency, soundproof blocks for noise control, and fire-rated CMU for added safety. There are also custom designs made for custom structural or functional needs.

These specialty blocks cost more than standard CMU, but they deliver targeted performance benefits. Choosing the right type saves money long term by solving the exact problem instead of adding extra materials later.

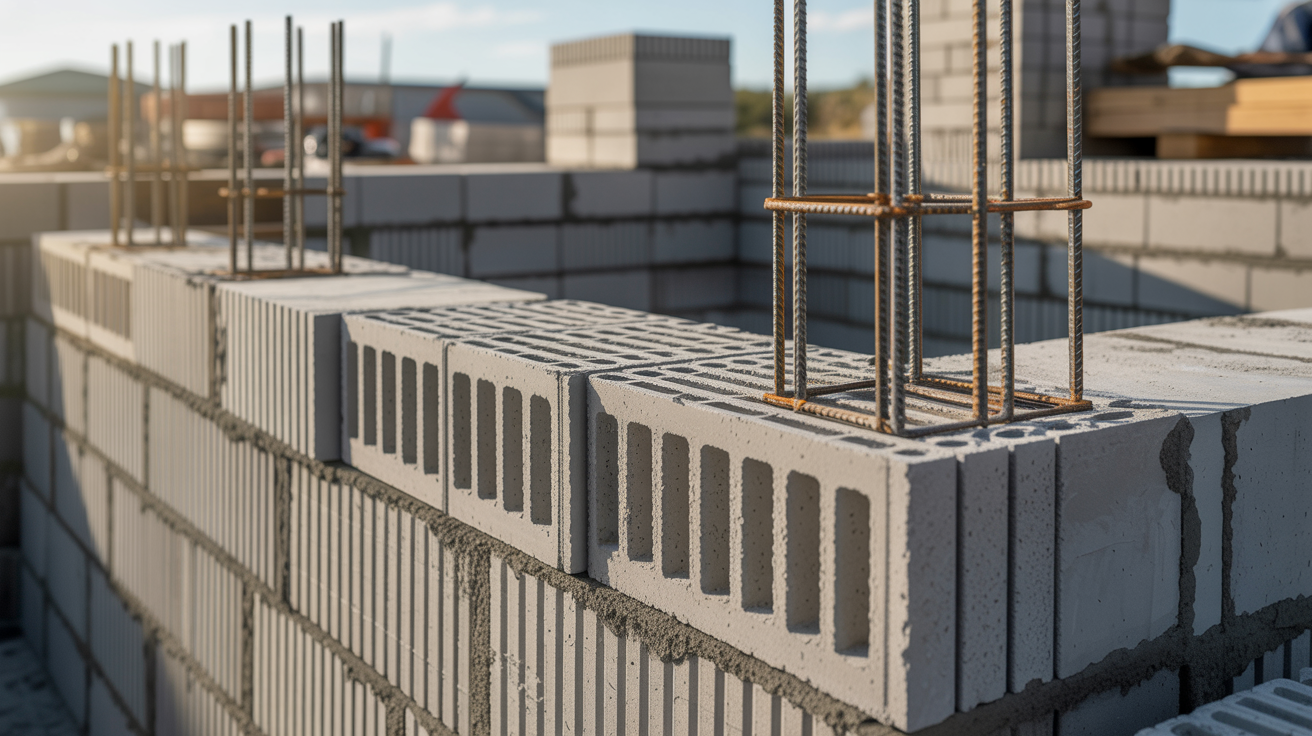

Hollow vs Solid CMU Blocks

Hollow blocks have two or more cores that reduce the block’s cross-section by about 25%. This design makes them lighter, easier to handle, and suitable for rebar placement to add strength when needed.

Solid blocks are used where extra strength or security matters, such as wall caps. They cost more and weigh more, so most projects rely mainly on hollow blocks with solid units used only in specific areas.

Special Block Shapes and Their Uses

CMU block shapes vary based on placement and function in a wall. Stretcher units handle wall length, while quoin, L-corner, and bullnose units finish corners and edges cleanly. Bond beam units create channels for steel and grout reinforcement.

Decorative options add visual interest without sacrificing structure. Scored stretchers mimic brick, while split flute and split wide units introduce texture and patterns.

Large projects often combine many block shapes to meet both design and structural needs.

Physical Characteristics of CMU Walls

The physical properties of CMU determine how it performs in real construction. Size, weight, and structural capacity all matter.

- Size and dimensions: Standard CMU is 8×8×16 inches, with many other sizes available for decorative or structural uses. Modular sizing allows precise planning and predictable construction.

- Weight and density: A typical CMU weighs about 30–35 pounds, depending on type. The density adds strength and sound control but makes handling and transport more demanding.

- Structural properties: CMU has high compressive strength and supports heavy loads well. It also resists weather, impact, and temperature changes, making it highly durable.

Pros and Cons of CMU Walls

CMU walls deliver serious strength and durability but come with weight challenges and insulation limitations. Understanding both sides helps you decide if CMU fits your project needs.

- Strength, durability, and fire resistance: CMU walls handle heavy loads, resist fire, moisture, and pests, and can last up to a century with minimal deterioration.

- Thermal mass and sound control: CMU regulates indoor temperatures naturally and blocks noise effectively, making it ideal for schools, hospitals, and busy locations.

- Versatility and cost-effectiveness: Suitable for foundations, walls, and landscaping, CMU offers strong performance at a lower cost with long-term savings from low maintenance.

- Low maintenance and sustainability: CMU resists rot, rust, and termites, uses recycled materials, reduces CO₂ impact, and is fully recyclable at the end of life.

- Weight and labor challenges: Heavy blocks require equipment, skilled labor, and more time, increasing physical strain and construction duration.

- Insulation and moisture limitations: CMU needs added insulation for energy efficiency and proper waterproofing to prevent moisture and mold issues.

- Design and production trade-offs: Visual options are limited compared to some materials, and production is energy-intensive despite long-term durability benefits.

CMU Wall vs Concrete Wall: Key Differences

People confuse these two options constantly. They’re related but definitely not the same thing.

|

Aspect |

CMU Walls |

Poured Concrete Walls |

|

Construction Method |

Built from individual concrete blocks stacked with mortar |

Poured as a single solid mass into forms |

|

Design Flexibility |

Modular units allow easier design changes and variations |

Seamless structure with no block joints |

|

Labor & Skills |

Requires skilled masons |

Requires form builders and concrete finishers |

|

Structural Makeup |

Hollow cores can be reinforced with steel and grout |

Solid, monolithic structure throughout |

|

Strength & Durability |

Strong but relies on mortar joints, which can be weak if poorly done |

Higher overall strength and long-term durability |

|

Typical Applications |

Commercial buildings, homes, interior and exterior walls |

Foundations, retaining walls, heavy-load structures |

|

Cost & Scheduling |

Often more cost-effective and easier to phase construction |

Higher labor cost due to forms and continuous pours |

CMU vs Other Building Materials

CMU competes with several other materials. Here’s how it stacks up in real-world comparisons.

CMU vs Traditional Brick

Material composition differs significantly between these two masonry options. CMU is larger in size than brick, so walls go up faster.

Thermal and acoustic properties vary between them. CMU offers superior structural strength per unit, while brick may have visual advantages that some prefer.

Brick looks more traditional and residential. CMU looks more commercial and industrial. Both have their place depending on project goals.

CMU vs Wood Construction

CMU offers vastly superior fire resistance compared to wood. Durability greatly exceeds wood in harsh conditions and over long time periods.

Wood doesn’t rust, but it can rot from moisture and insect damage. CMU is termite-resistant and doesn’t rot, making it more reliable long-term.

Different applications suit each material. Wood for residential framing, CMU for foundations and commercial structures. They often get used together in the same building.

CMU vs ICF (Insulated Concrete Forms)

ICF is gaining popularity because it delivers built-in insulation on both interior and exterior sides. Lightweight foam forms stack easily, then concrete is poured inside for a solid core.

Compared to CMU, ICF is easier to handle and faster to build. Projects often need 50% less labor, with better airtightness, sound control, and resistance to fire, wind, and seismic forces.

While CMU still works well for many builds, ICF shines where energy efficiency and speed matter most. When insulation and labor are factored in, total wall assembly costs are often lower with ICF.

Cost Analysis of CMU Walls

Money matters in construction. Here’s what CMU actually costs when you break it down.

Material Costs

CMU is generally affordable compared to many alternatives. Pricing varies by type, with standard blocks the cheapest and specialty blocks costing more.

Hollow blocks cost less than solid ones since they use less material. Regional availability affects pricing, so check local suppliers for actual numbers.

Material costs are usually the smaller part of the total project expense. Labor often costs more than materials for CMU work.

Labor and Installation Costs

Skilled labor costs increase the total project expense significantly. CMU installation is time-intensive compared to some faster building methods.

Equipment needs for handling heavy blocks add to costs. Forklifts or telehandlers might be necessary on larger projects.

Total project costs include materials, labor, equipment, and time. CMU requires more labor hours than some alternatives but fewer than others.

Cost Comparison with Alternatives

CMU costs less than some materials for large projects. It’s more economical than certain high-end options like natural stone or specialized systems.

ICF may offer lower completed wall assembly costs when you include all insulation and finishing layers. Consider total project costs, not just material prices per unit.

Get quotes for complete wall systems, not just base materials. The true cost comparison includes everything needed for a finished, code-compliant wall.

Maintenance and Longevity

CMU’s low maintenance needs are a huge advantage. Here’s what actual upkeep involves.

- Routine maintenance: CMU needs minimal upkeep, mainly monitoring cracks and addressing moisture with occasional resealing or coatings.

- Common issues: Moisture, cracks, and mold are the main concerns, usually prevented with good waterproofing, drainage, and ventilation.

- Lifespan: With proper care, CMU structures can last up to 100 years, often remaining functional for multiple generations.

Conclusion

You now understand what CMU walls mean and why these concrete masonry units matter in construction. They are commonly used for foundations, homes, and commercial buildings because they offer strength, safety, and long-term value at a reasonable cost.

CMU walls come with clear benefits. They last for decades, require little upkeep, and work in many building situations. While their weight and insulation needs require planning, those concerns are manageable with proper design.

You also know how CMU compares to options like poured concrete and insulated block systems. Each choice has trade-offs based on budget, schedule, and project needs. There is no confusion now when builders mention CMU. You can ask informed questions, understand recommendations, and make confident decisions when planning your build.

Frequently Asked Questions

What does CMU wall mean in construction?

CMU stands for Concrete Masonry Unit. It refers to standardized rectangular blocks made from Portland cement, aggregates like sand or crushed stone, and water. These blocks are stacked with mortar to create walls in residential, commercial, and industrial buildings.

How long do CMU walls last?

CMU walls can last up to 100 years with proper maintenance. The concrete materials resist deterioration over time, making them highly durable. Maintenance mainly involves addressing cracks and moisture issues. Their longevity often exceeds many other building materials.

Are CMU walls expensive?

CMU walls are generally affordable compared to other building materials. Material costs are reasonable, and blocks are widely available. However, installation requires skilled labor and can be time-intensive, which increases overall project costs. Long-term savings come from low maintenance needs.

What’s the difference between CMU and concrete walls?

CMU walls use individual stacked blocks with hollow cores, reinforced with steel and mortar. Concrete walls are solid, monolithic structures made from poured concrete. CMU offers design flexibility, while concrete walls provide higher strength for foundations and heavy-duty applications.

Do CMU walls need insulation?

Yes, CMU walls typically need additional insulation for energy efficiency. While they provide good thermal mass that regulates temperature, their innate insulation properties are limited. Adding insulation helps meet modern energy standards and reduces heating and cooling costs significantly.